Quality management policy

At Iutech Wear, our Quality Management Policy is the cornerstone of our commitment to delivering superior products. We adhere to rigorous standards throughout every stage of our production process, from supplier selection to final inspection. By enforcing strict quality controls and continuous monitoring, we ensure that every smartwatch meets our exacting criteria for performance, durability, and safety. Our policy is designed to foster a culture of excellence, where every detail is scrutinized to guarantee that our customers receive only the best. Through ongoing evaluation and improvement, we remain dedicated to maintaining the highest level of quality in all that we do.

Quality management organization structure

At Iutech Wear, our Quality Management Organization Structure ensures every product meets the highest standards. Our team, from top leadership to inspectors, integrates quality control at every production stage. This cohesive system prioritizes precision, accountability, and continuous improvement, making quality a fundamental aspect of everything we do, ensuring our commitment to excellence is consistently upheld.

Whole process quality assurance

Reliability Laboratory

- Test Standard of Environmental Equipment

- Test Standard of Machinery Packaging

Test Standard of Environmental Equipment

At Iutech Wear, we maintain rigorous standards for our environmental equipment to support eco-friendly manufacturing. We test emission controls, conduct energy audits, manage waste, and monitor water usage and noise levels. These practices underline our commitment to sustainability and high-quality smartwatch production.

Test Standard of Machinery Packaging

At Iutech Wear, we enforce strict testing standards for machinery packaging to ensure durability and safety during transit. Our protocols assess material strength, shock absorption, and environmental resistance, guaranteeing that our products arrive in pristine condition while supporting sustainable packaging practices.

Test Standard of Machinery Packaging

At Iutech Wear, we enforce strict testing standards for machinery packaging to ensure durability and safety during transit. Our protocols assess material strength, shock absorption, and environmental resistance, guaranteeing that our products arrive in pristine condition while supporting sustainable packaging practices.

ITFool-proofing

Project phase I

Start-up preparation phase

Internal research

Understand the business needs of the manufacturing department, and output the business needs confirmation. Plan a demonstration production line, arrange and gradually roll out the timetable for a comprehensive application plan

System selection

The business department determines the MES system selection, confirms the modules and main functions, and the IT information department is responsible for technical confirmationProject phase II

Start-up implementation phase

Network hypothesis

The factory line body carries out industrial network construction, and wired and wireless information points provide hardware support for information collection.

Core system

The main system and test module system environment and database environment have been set up, and the internal test before going live has been completed.System training

Complete pre-launch trainingProject phase III

On-line application stage

Officially launched

The demonstration line officially started MES system management and applied systematic management processes.

Equipment integration

Data collection and interface development of intelligent equipment are carried out at the same time.Kanban and report

After the quantitative data is collected, the hypothesis of the kanban and the custom development of the report form are carried out.Project phase IV

System integration and mature extended application

System integration

After the MES operation is mature and stable, cross-system interface integration development work will be carried out to realize data interaction between systems.

Extended application

Secondary development of extended functions.System operation

Ensure the effective operation of the system.

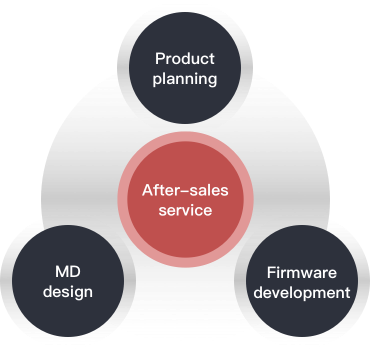

After-sales service

At Iutech Wear, our after-sales service is pivotal, ensuring customer satisfaction and longevity of our products. It integrates with key areas like product planning, MD design, and firmware development to offer comprehensive support. This approach guarantees effective problem-solving and enhances the overall user experience with our smartwatches.